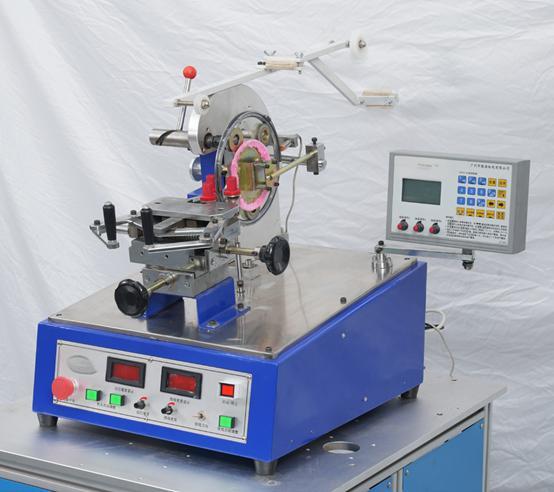

LY2610 Edge-sliding high-speed toroidal coil winding machine

Description

SPECIFICATION:Main technical parameters table: (Unit: mm)

device type | toroid coil winding machine |

Winding method | Side sliding type |

Finally complete the outer diameter | 30/80 mm |

Minimum completed inner diameter | 12 mm |

Maximum completion height | 50 mm |

Suitable winding diameter range | 0.12-0.5 mm |

Diameter of storage ring | 180 mm |

Width of storage loop | 3-6 mm |

Maximum speed | 800 RPM |

Working Voltage | 220 V/50 HZ |

Pre programmable program | 50×20 Group |

Overall dimension | 480 x 45 0x 600 mm(L*W*H) |

Total machine weight | 90 KG |

Equipment features

▶ Adopting the edge sliding winding method, it is suitable for winding products with thinner wire diameters and more turns, such as primary coils of transformers, small transformer coils, etc. It has high winding speed, is not easy to scratch paint, and is not prone to breakage.

▶ There are various types of wire suitable for winding, such as enameled copper wire, enameled aluminum wire, steel wire, heating wire, etc., which are suitable for coil processing of products in various industries.

▶ The machine head is driven by a synchronous belt, which has the characteristics of low operating noise, long service life, and maintenance free.

▶ The storage ring is driven by soft rubber wheels, which are not easy to slip and wear out, making the equipment more durable.

▶ The maximum winding speed can be freely set according to the size of the wire diameter.

▶ When wiring, the automatic rotation of the wiring function is used to reserve lead positions for transformers with a large number of turns.

▶ The maximum speed of storage and winding can be adjusted separately, which significantly improves production efficiency when winding small wire diameter products and the winding speed cannot be too fast.

▶ Multiple wire storage and winding can be set. For products with an additional number of turns that cannot store enough wire, winding can be completed in one go.

▶ The cable density (speed) can be automatically changed when running different programs, and can be automatically completed when winding products with multiple taps but different turns and the same cable angle/requirements.

ADVANTAGES:

1.Stable machine performance

2.Communicate parameters in a timely and thoughtful manner

3.Wide range of application, Large range of Speed adjustment, wide range of the wire diameter, Multi-style of core, Brake tension adjustable, Good settlement for large outer diameter, small inner diameter, heavy wire coils.

4.High production efficiency, increase winding efficiency by adjustment of suitable brake tension,

5.Each wiring part guarantee no wire damage.

6.Parts highly optimized and universal for general use, Easy maintenance

7.Complete specifications and data